The manufacturing industry is currently navigating a complex landscape. Supply chain disruptions, rising material costs, and increasing demands for customization are forcing companies to seek innovative solutions to maintain profitability and competitiveness. Amidst this upheaval, precision manufacturing remains paramount, and Computer Numerical Control (CNC) machine tools are at its core. One area ripe for significant improvement is the drive system – specifically, the utilization of micro DC gear motors. This article explores how these compact powerhouses are transforming CNC machining, leading to tangible cost reductions and significant efficiency gains.

Traditional CNC machine tools often rely on larger, less efficient drive systems. While robust, these systems can be expensive to purchase, maintain, and operate. Furthermore, their size and weight can limit the design flexibility of CNC machines, hindering advancements in miniaturization and complex geometries. Recent trends like additive manufacturing (3D printing) integrated with CNC finishing are further emphasizing the need for agile and efficient machine tools. The pressure to reduce energy consumption, a key area of focus in sustainability initiatives linked to the recent surge in ESG (Environmental, Social, and Governance) investing, also adds urgency.

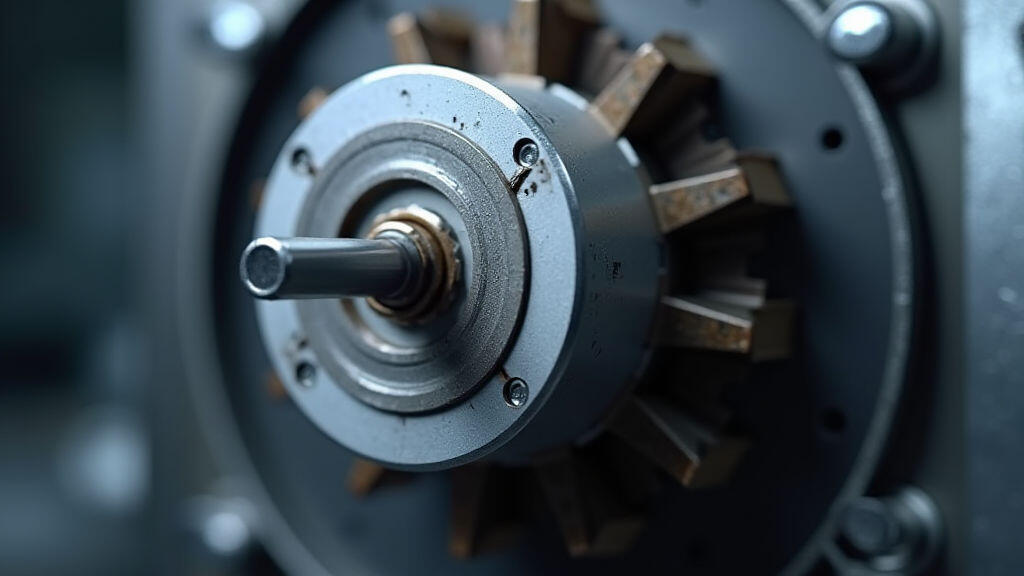

Micro DC gear motors offer a compelling alternative. These miniature motors combine the power of a DC motor with the speed reduction of a gear system, delivering high torque in a compact package. They excel in applications requiring precise control and efficient power delivery within constrained spaces.

Here's a breakdown of their advantages:

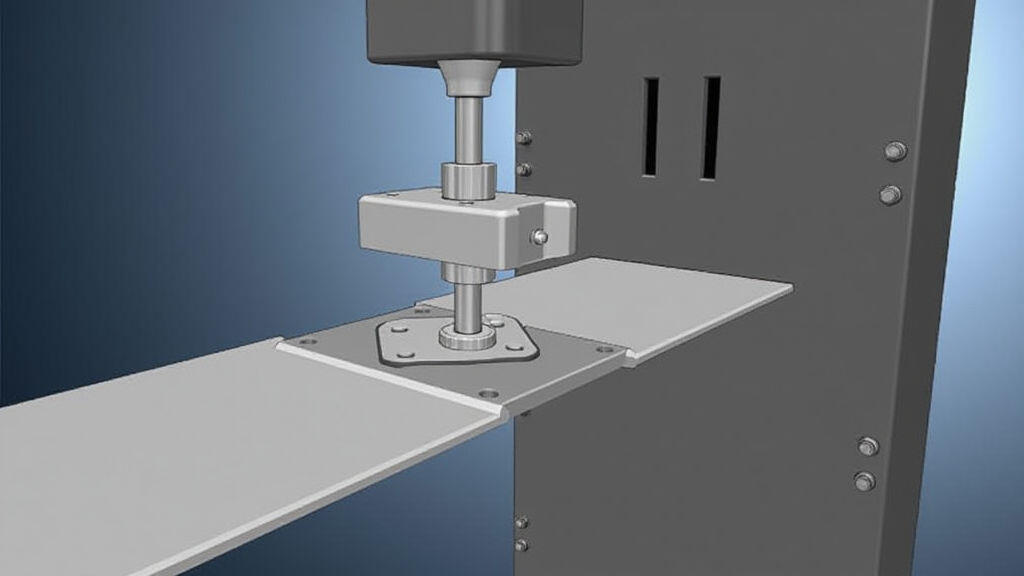

The integration of micro DC gear motors into CNC machines unlocks numerous cost reduction opportunities:

Beyond cost savings, micro DC gear motors drive significant efficiency improvements:

MES-Drive is a leading provider of high-performance micro DC gear motors specifically engineered for CNC machine tool applications. Their motors are designed for exceptional reliability, efficiency, and precision. MES-Drive offers customized solutions to meet the unique requirements of various CNC machines, from small-scale hobbyist machines to large-scale industrial setups. They also provide comprehensive support, including application engineering, technical assistance, and training.

The trend towards smaller, more efficient, and more adaptable CNC machine tools is undeniable. As the manufacturing industry continues to evolve, the role of micro DC gear motors will only become more critical. The drive towards Industry 4.0, with its emphasis on automation, data analytics, and real-time control, further accelerates this trend. Furthermore, the renewed focus on reshoring manufacturing to developed economies requires investment in modern, efficient equipment.

The growing importance of sustainability and ESG compliance creates a major impetus for adopting energy-efficient technologies. Micro DC gear motors, with their low energy consumption and long lifespan, present a compelling solution for manufacturers seeking to reduce their environmental impact. The current discussions around the CHIPS Act and similar initiatives further encourage investment in advanced manufacturing technologies, where micro DC gear motors play a key enabling role.

In conclusion, micro DC gear motors are not just a component; they are a catalyst for transformation in the CNC machining industry. By delivering significant cost reductions, efficiency improvements, and enhanced flexibility, these compact powerhouses are empowering manufacturers to thrive in a challenging and competitive environment. As the industry embraces Industry 4.0 and prioritizes sustainability, the demand for micro DC gear motors is poised to soar. MES-Drive and other innovative companies are leading the charge, driving the future of precision manufacturing.

Leave A Reply

Your email address will not be published. Required fiels are marked